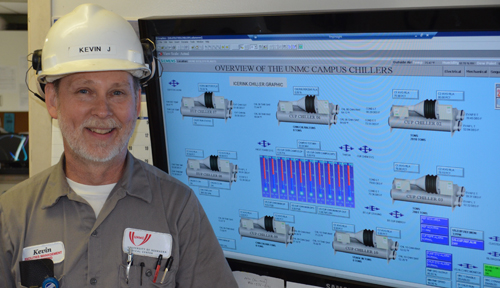

Kevin Jespersen is monitoring your air conditioning.

Seated at a big screen console in the control room of the Facilities building, Jespersen and other team members monitor the campus’s massive chillers, boiler and high voltage electrical system.

“It’s basically the same system you have on your refrigerator, just really supersized and optimized for the loads we serve on campus,” said Darren Dageforde, director of utilities.

From his computer, Jespersen is currently checking chiller tonnage, water flow and the load each chiller is handling. He clicks from screen to screen, noting water levels, cooling efficiencies, and supply and return temperatures as water moves through the system.

|

Sound complex? It is.

Jespersen is a member of the utilities department of the Facilities Management Planning team, 20 people working in a 40,000-square-foot building, tasked with keeping the air cool in the summer and warm in the winter — no mean feat on a sprawling campus.

Jespersen, who has been at UNMC for more than 30 years, considers “finding problems early” the most satisfying part of his job.

Something as seemingly minor as a discrepancy in water levels in the chillers can provide red flags that can lead an alert technician to literally stop a problem before it begins.

“There’s a sweet spot where the efficiency is the best, and we try to run in that range,” Jespersen said.

“While computers can be programmed to evaluate a lot of data, you can’t replace the cognitive capabilities of the human operator to prevent the little ‘bumps’ in the processes that are really expensive when the power bill arrives,” Dageforde said.

Technicians monitor all heating and cooling industrial processes to make sure nothing goes wrong, Jespersen said. Water level in the cooling tower, how many fans are running, pump speeds and how well the pumps are working — all of this and more can be seen from Jespersen’s station.

“When things are running along normally, no one really has any reason to contact us or even know who we are. It’s a state of obscurity that means things are going well that we kind of enjoy,” Dageforde said.

So what happens when something goes wrong?

“We get it fixed, fast. The longer problems are allowed to stay around, the faster the negative consequences pile up and the more customers are affected,” he said. “Not only will it cost more to fix — we lose our obscurity.”

Good job guys!!!